Over a third of workplace hand injuries involve cuts.

This may sound like bad news, but it’s unquestionably a unconfined opportunity, considering hand injuries are the #1 preventable workplace injury.

Often hand injuries occur considering workers are wearing the wrong hand protection (or worse, no hand protection!) Unfortunately, the myriad safety glove options on the market can make it difficult to segregate the right protection.

How do you know which gloves offer the level of cut resistance your workers need without inhibiting their work and comfort?

Push

(downward force)

This gravity is generated by a sharp object pushing lanugo on a material – whether that is glove material or skin doesn’t matter. This downward gravity creates tension in the material leading it to tear.

Pull

(Friction Force)

This gravity is created by the slicing motion of a stipule wideness a material. As the stipule moves across, the friction created pulls yonder (cuts) the fibers of the material.

So, how are these forces counteracted?

Counterforces That Minimize The Effects Of Push And Pull

There are four main forces that can counter the push and pull forces that contribute to cut injuries.

Strength

Hardness

Lubrication (slickness)

Roll

To counteract friction gravity (the slicing motion), we engineer materials to provide lubrication and rolling action. This allows the sharp objects like blades to travel increasingly hands wideness the material, reducing the friction that causes cuts.

Understanding the science overdue these forces helps glove manufacturers engineer cut-resistant materials for safety gloves. Industry standards moreover wield these same forces to test and measure the effectiveness of cut-resistant gloves and assign them protection levels.

HPPE vs. Para-aramid

Cut-resistant gloves made of 100% HPPE or para-aramid both offer up to ANSI Cut Level A3 protection. HPPE, however, outperforms para-aramid when it comes to comfort. Gloves made with 100% HPPE are softer, increasingly flexible, and finger potation on the skin in comparison to para-aramid. But para-aramid has the wholesomeness of natural flame and heat resistance, which can make it a largest nomination for workers who need this uneaten protection.

All-Metal Chainmail Gloves

Although less common, metal can be used as the only material in manufacturing cut-resistant gloves. These gloves are known as chainmail gloves. Chainmail gloves are made of metal rings linked together in a pattern to form mesh and are primarily used in supplies processing for deboning meat. The gloves offer an extremely upper level of cut resistance but they significantly limit the user’s range of motion.

Composite/Engineered Yarn

The key to manufacturing highly cut-resistant gloves that are well-appointed is composite or engineered yarn. Engineered yarns incorporate the benefits of two or increasingly fibers, instead of solely relying on one strong fiber. Combining materials within the yarn allows gloves to maintain repletion while increasing protection. When two cut-resistant materials such as HPPE and metal are combined, the resulting webbing can unzip up to ANSI Cut Level A9, the industry's maximum level of cut protection. In addition, synthetic fibers like nylon or polyester and natural fibers such as cotton can be widow into the yarn to enhance comfort, dexterity, and durability.

Gauge is refers to the number of stitches included in each inch of yarn. As the number of stitches increases, so does the gauge. This ways the yarn is thinner, permitting for a thinner glove. When there are fewer stitches per inch of yarn, the yarn is thicker and thus the glove is thicker. Note: although gauge refers to yarn, you’ll often here the term “glove gauge”.

This carries the same meaning. It is simply a shorthand way to refer to glove thickness.

…

Below is a quick overview of glove gauges, including their thickness and attributes, to requite you an idea of how gauges impact a glove’s finger and performance in tasks that involve cut hazards.

Different gauges are recommended for variegated tasks and hazards. No one gauge is largest than the other. It depends on the work task and hazards for which they’re needed.

For instance, if comparing a 7-gauge glove to a 21-gauge glove, the 7 gauge will be less dexterous, considering it’s less flexible and has a lower tactile feel. If fine motor skill is needed, this is an issue. But, if the task requires heavy lifting that includes sharp and undermining objects, someone might prefer thicker glove as it offers increased cushioning and durability.

To learn increasingly well-nigh the differences between glove gauges, trammels out our Glove 101 section on glove gauges that discusses the topic in detail.

Does palm coating increase cut resistance?

The short wordplay is no!

A slightly longer subtitle is that the changes are nominal, so palm coating shouldn’t be viewed as uneaten protection.

However, palm coatings do provide improved grip that can midpoint fewer slips with sharp objects, and thus potentially less opportunities for cuts. Palm coating moreover helps proffer the life of the shell.

As such, palm coating should be considered when choosing a cut-resistant glove.

Check out our Glove 101 section on palm coating for increasingly information well-nigh types of palm coatings and the work conditions they’re weightier suited to.

To solve this problem, industry standards were established that refer to specific test methods to assign protection levels for safety gloves, including cut resistance. These standards were introduced to create a worldwide language for safety managers, distributors, and manufacturers to pinpoint protection levels and be held subject for their claims.

There are three industry standards governing cut protection:

North American Standard (ANSI/ISEA 105)

The ANSI/ISEA Standard established the ASTM F2992-15 standardized testing method for measuring cut resistance. The standard identifies nine cut protection levels from A1 (least cut resistant) to A9 (most cut resistant).

Manufacturers must test products in vibrations with the standard’s testing procedure in order to legitimately requirement a protection level. To ensure gloves have the level of protection they claim, squint for protection ratings icons that resemble a shield as pictured below. You can moreover ask a manufacturer to provide a reprinting of test results to substantiate protection claims.

Testing Method:

A Tomodynamometer Machine (TDM-100) is used to self-mastery the cut-resistant test on gloves. Materials are tested under three varied weights with a straight-edge stipule that moves wideness five times in the same direction at approximately the length of 20mm. Without each cut, a new stipule is used, and the weight (in grams) is widow until a cut is achieved. The test is repeated a total of three times and the stereotype of the three tests gives the final rating in grams, ranging from 200 grams to 6000 grams of cut resistance. This determines a cut score between A1-A9.

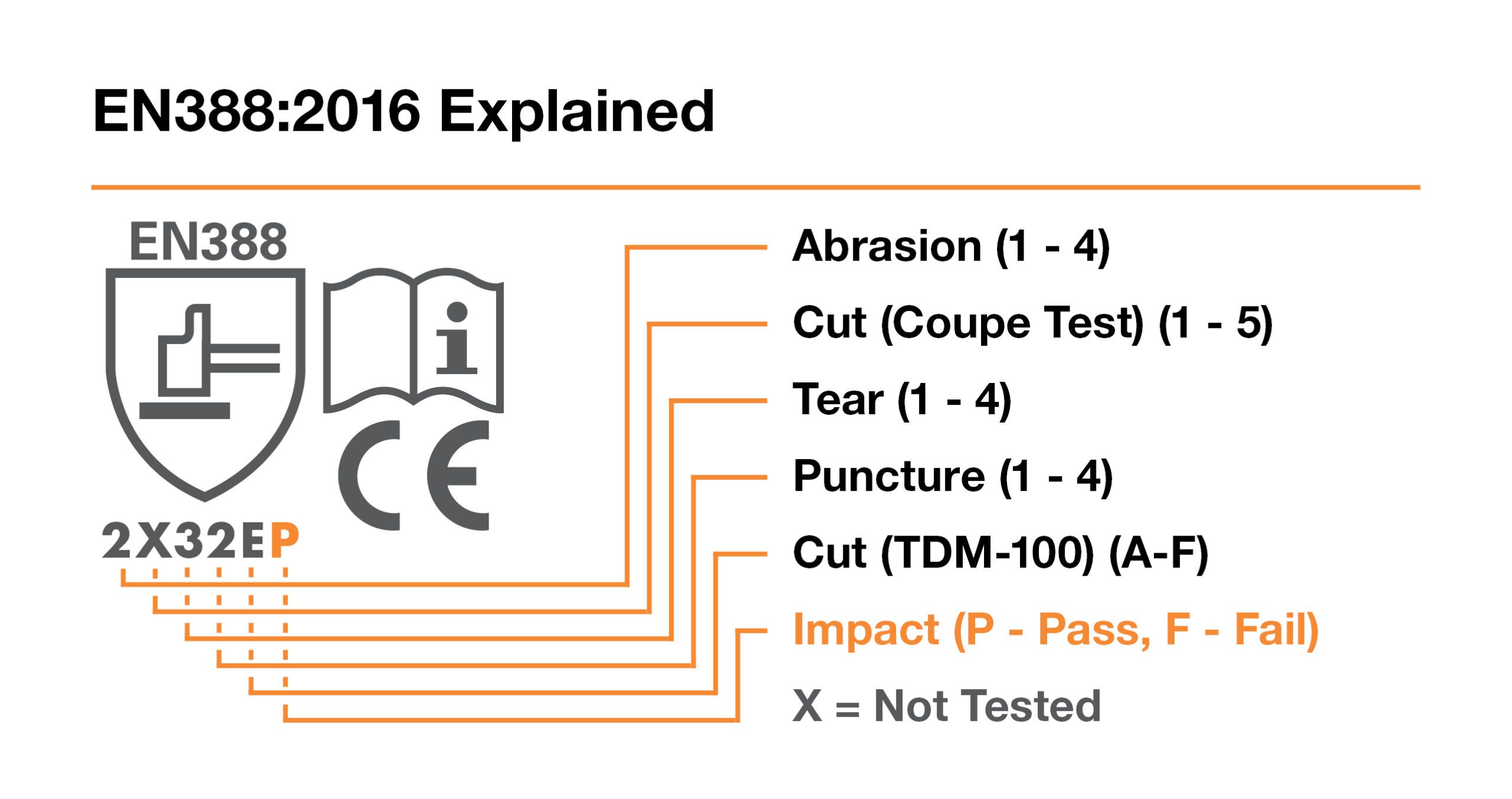

EN388 European Standard

The EN388 Standard uses two variegated testing methods to evaluate protection ratings.

1. The Coup Test

- Rates cut protection on a scale of 1-5 (least to most cut resistant)

2. The TDM-100 Test (also known as ISO 13997 testing method)

- Rates cut protection on a scale of A-F (least to most cut resistant)

- Similar to the North American ANSI/ISEA testing standard

Manufactures must test products in vibrations with the standard’s testing procedure in order to legitimately requirement a protection level. To ensure gloves have the level of protection they claim, squint for protection rating icons that resemble a shield as pictured below. You can moreover ask a manufacturer to provide a reprinting of test results to substantiate protection claims.

Testing Method:

Coup Test: In this test, test material is placed underneath a rotating circular stipule that moves when and along under a stock-still weight until cut-through occurs. A cut score is recorded on a scale of 1-5. The problem with this testing method is that the stipule dulls if used on upper cut-resistant material, which results in inaccurate scores.

If no cut-through occurs without 60 rotations, the second test is used and required: the ISO 13997. The result is measured in Newtons.

ISO 13997: The ISO 13997 uses the TDM-100 test method which uses a straight razor stipule under variable weight to measure cut resistance, similar to the ASTM F2992-15. Results are measured in Newtons, ranging from 2-30 Newtons, and are graded from A-F. Cut resistance for materials tested using this method will only have an “X” placed under the Coup Test score marking to indicate “not tested” on the EN388 Standard shield. An example of this can be seen in the image below.

UK Conformity Assessed (UKCA) Standard

There are no differences in the testing methods and ranking levels between the European Union and United Kingdom standards. However, PPE sold in the UK is mandated to have an icon (as shown) to certify they conform with UKCA (UK Conformity Assessed)

Now that you have a vital understanding of how cut-resistant gloves work, let’s review some worldwide misconceptions well-nigh cut resistance.

Misconception 1:

Cut-Resistant Gloves Are Cut-Proof

There is no such thing as cut-proof gloves. To be wearable, gloves must have properties that indulge them to move, flex, be pulled on and off, etc. -properties that cannot be considered impenetrable. So, if you use scissors to cut these gloves, you can cut them! Plane all-metal chainmail gloves can be cut with unbearable determination.

Cut-resistant gloves are, however, designed to reduce the likelihood of stuff cut. Although cut injuries can still occur plane when wearing gloves, cut severity can be drastically reduced when not prevented.

Misconception 2:

Leather is Cut-Resistant

Due to its upper durability, many think leather is cut-resistant. Leather is simply cured skin, and skin isn’t cut-resistant. Leather gloves can only offer significant cut protection when they have an widow cut-resistant liner. These liners are made from the same materials discussed older in this article.

Misconception 3:

360° Cut Protection is the Testing Standard

Testing standards for cut resistance only require the palm of the gloves to be tested. For this reason, the ANSI cut level ratings prescribed to cut-resistant gloves denote resistance levels for the palms only and not the rest of the glove.

This is the icon we use on information well-nigh gloves that provide 360° cut protection. Although there are no cut resistance test requirements for the rest of the glove, manufacturers should be well-spoken well-nigh which gloves provide 360° of cut resistance.

Getting self-ruling samples is easy. Request up to three variegated product samples by subtracting them to your Sample Box. Just like an online shopping cart.

The post Everything You Need To Know Well-nigh Cut-Resistant Gloves appeared first on Superior Glove.